Dr. Phil Phillips

President & Managing Director

Contributing Editor

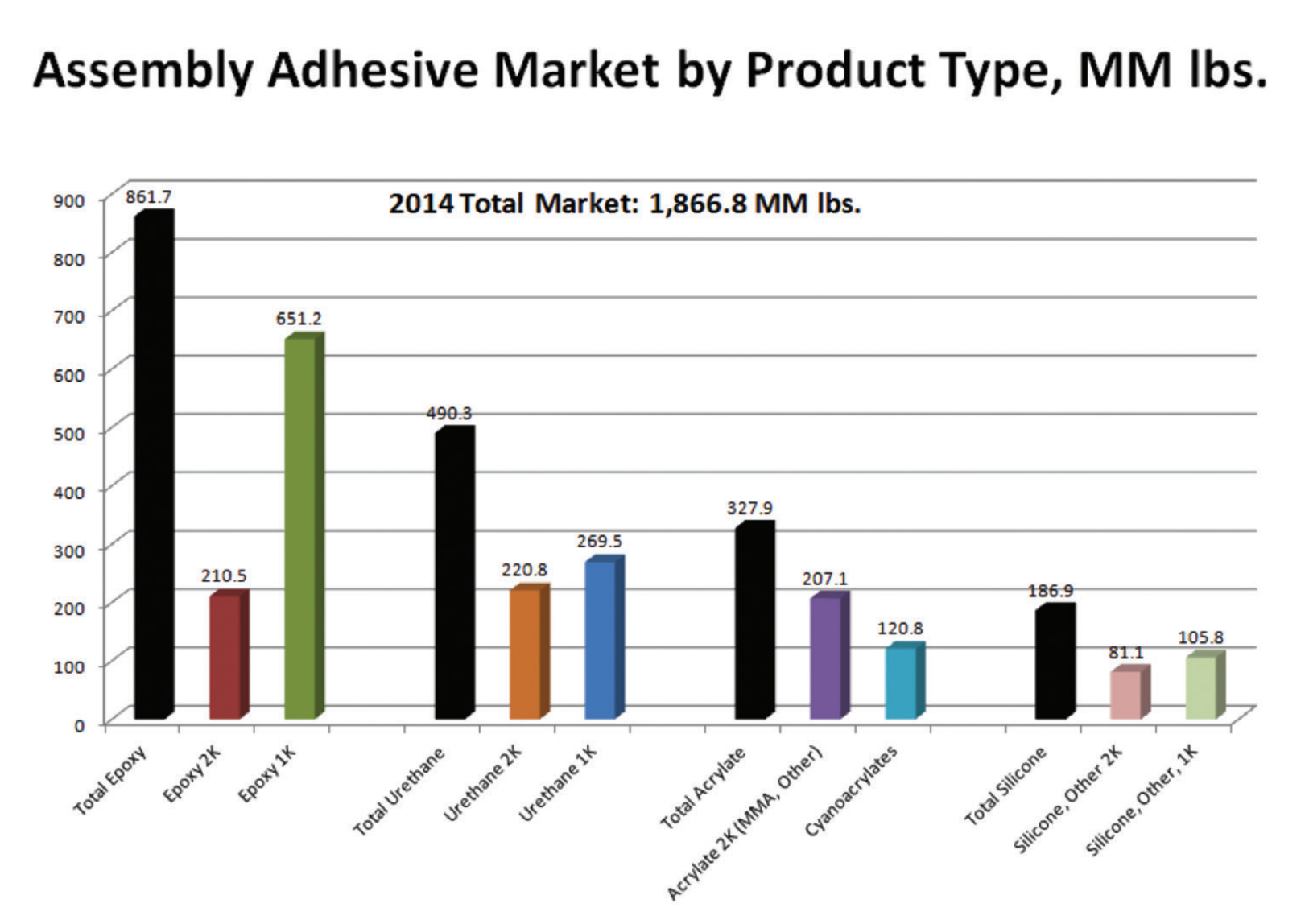

The world’s industrial regions are moving, as one, in their use of structural adhesives within major assembly markets. We estimate the global use of structural assemble adhesive systems at 6.5 Bn pounds and valued at $16.0 Bn USD. North America at 28.6% share of this global market, is 1,867MM in volume and growing at between 4.8% and 5.2% annually. Epoxies lead the NA assembly market by 43.2% over the next leading resin technology – urethanes at $490.3MM while acrylics are 61.9% behind epoxies at $328MM with silicones at $187MM, 78.3% behind the leader, epoxies. There are three sectors of the structural adhesives marketplace: commodity, transitional and high value.

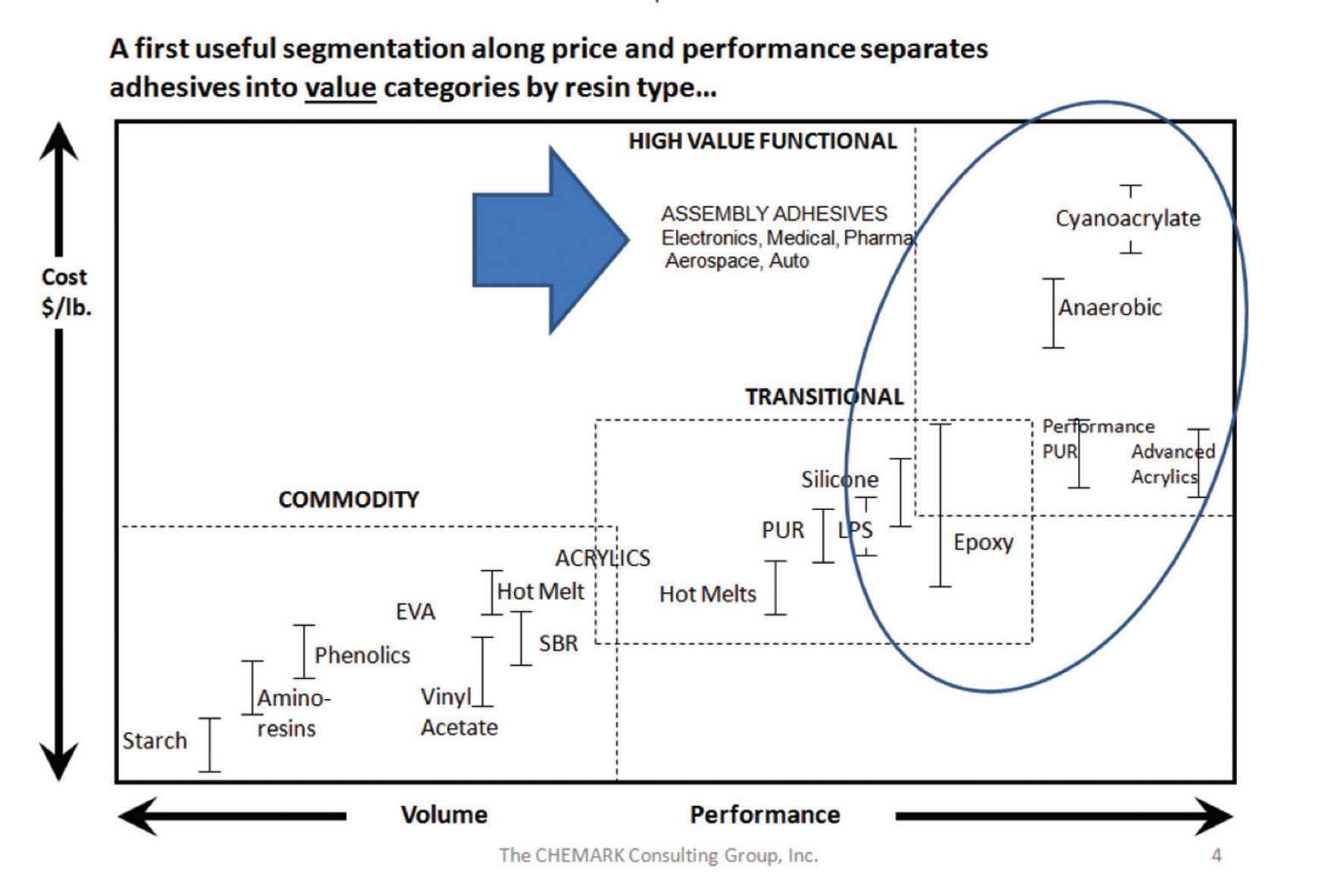

Commodity is characterized by high volume, low prices, low-profit contribution and weak physical performance. Transitional assembly adhesives is characterized by modest volume, mid-range pricing, greater profit contribution and modest performance while high value assembly adhesives has low relative volume, highest prices & profit contribution and outstanding performance.

By generic resin type, the graph shows the relative value streaming from left (low) to right (high).

The NA Assembly Adhesives Market has 13 major segments and range in size and share of market space from the two largest at 36.2% & 34.5%, Automotive OEM and Building & Construction, respectively to the smallest RV Transportation at 0.5%.

The segments with the fastest growth in rank order are:

- General Electrics

- Wind energy

- Aerospace

- Automotive OEM

- Building & Construction; General Assembly; Transportation-Truck/Bus

- Auto Aftermarket; Transportation-Marine; Appliance

- Transportation-RV; Transportation-HD

- Transportation-Rail

One of several drivers in the faster growth segments is the use of smart/functional adhesives systems. For example, Nanotubes are starting to aid functionality by improving adhesive bonding at lower bead thicknesses while providing miniature electric circuitry which can reduce road noise in Auto applications.

Other applications where nano-containing assembly adhesive systems are either being commercially introduced or are being seriously considered are:

- Electronic – miniaturization bonding

- Aerospace, Wind Energy, Transportation, General Assembly – weight reduction programs

Your comments and inquiries are always welcome.